How is the functionality of the concrete water treatment?

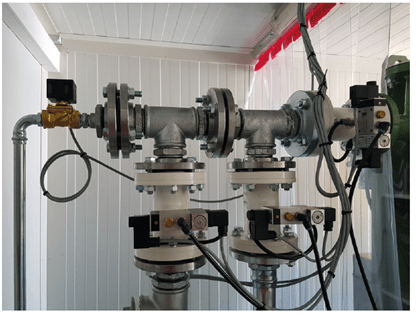

The waste water cleaning in CWAS 2.0 water treatment system works with the principle of water density standardization. What does this mean?

The system specifically reduces the water density of the residual concrete water to a freely selectable, adjustable value and thus creates the prerequisites for the complete reuse of this water for concrete production. In addition, the operator avoids excessive sediment waste, as only as much sediment is removed from the residual water basin as necessary. At the end of the day, the patented process enables the sediments removed from the water to be processed so that this waste, which normally has to be disposed of, can be reused as an aggregate in concrete production.

Advantages of the water-density-standardization:

- Any residual water around the concrete production can according to DIN EN 1008 be used again. The prerequisite is compliance with the permitted parameters of the water specification for concrete production.

- The water density standardization uses intelligent and extremely robust control technology to set a constant water density in the gray water basin.

- Minimized costs for residual water disposal (especially in winter)

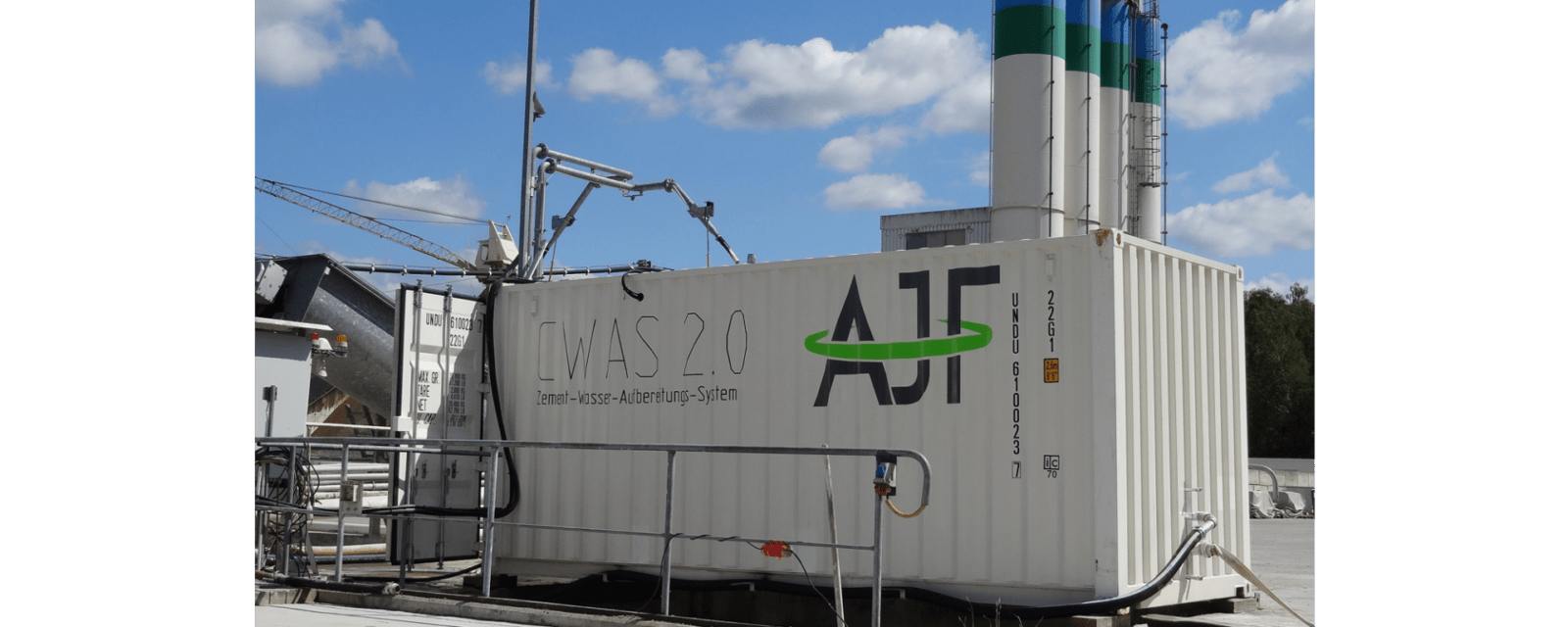

- Another advantage is the mobility of the system. This can be used at another location within a very short time.